A3-PT3+GS-9C+

GP6000-2+BQJ-H

SEWING EQUIPMENT

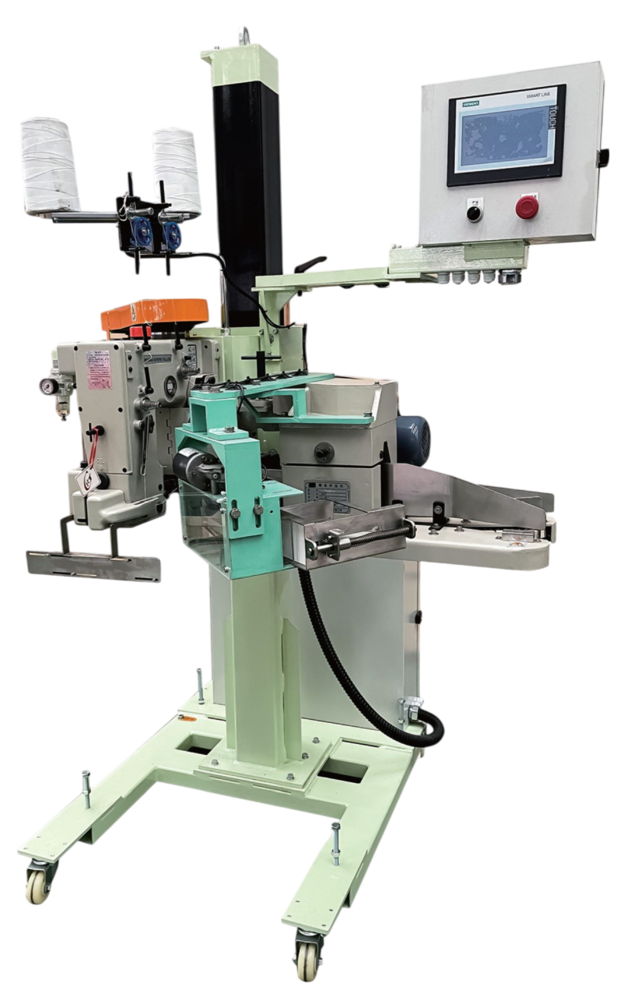

The overall material is carbon steel, which is suitable for applications in various industries. Movable casters are convenient to move the equipment, and the base is strengthened to ensure the stability of the equipment. The whole plate is cut and welded, with beautiful appearance and reliable quality.

The GS-9C bag sewing machine adopts a sealed built-in oil tank lubrication system. It is the fastest sewing machine on the market today. It is suitable for all kinds of bags; the speed can reach 25 m/min.

The automatic labeling machine consists of a motor control system, a belt conveyor system, and a mechanical gripper system. The start and stop of the whole machine is controlled by a photoelectric switch, and its speed can be adjusted arbitrarily according to the speed of the production line, which is suitable for the automatic labeling of the bag mouth in various industries.

GP6000-2 chain folding device is the company latest developed automatic plastic woven bag bending unit, which has the characteristics of advanced structure, large adjustment range, superior folding performance, simple operation and convenient maintenance. It can be comparable with the international advanced one! The packaging bag sealed performance is greatly improved after folding by this unit. The package is firmed, loose package, missing package phenomena are effectively prevented. It can be installed on the pedestal and used together with GK35 series sewing head and GS-9 series sewing head. Widely used in the packaging production line of grain, chemical industry, port and other industries.